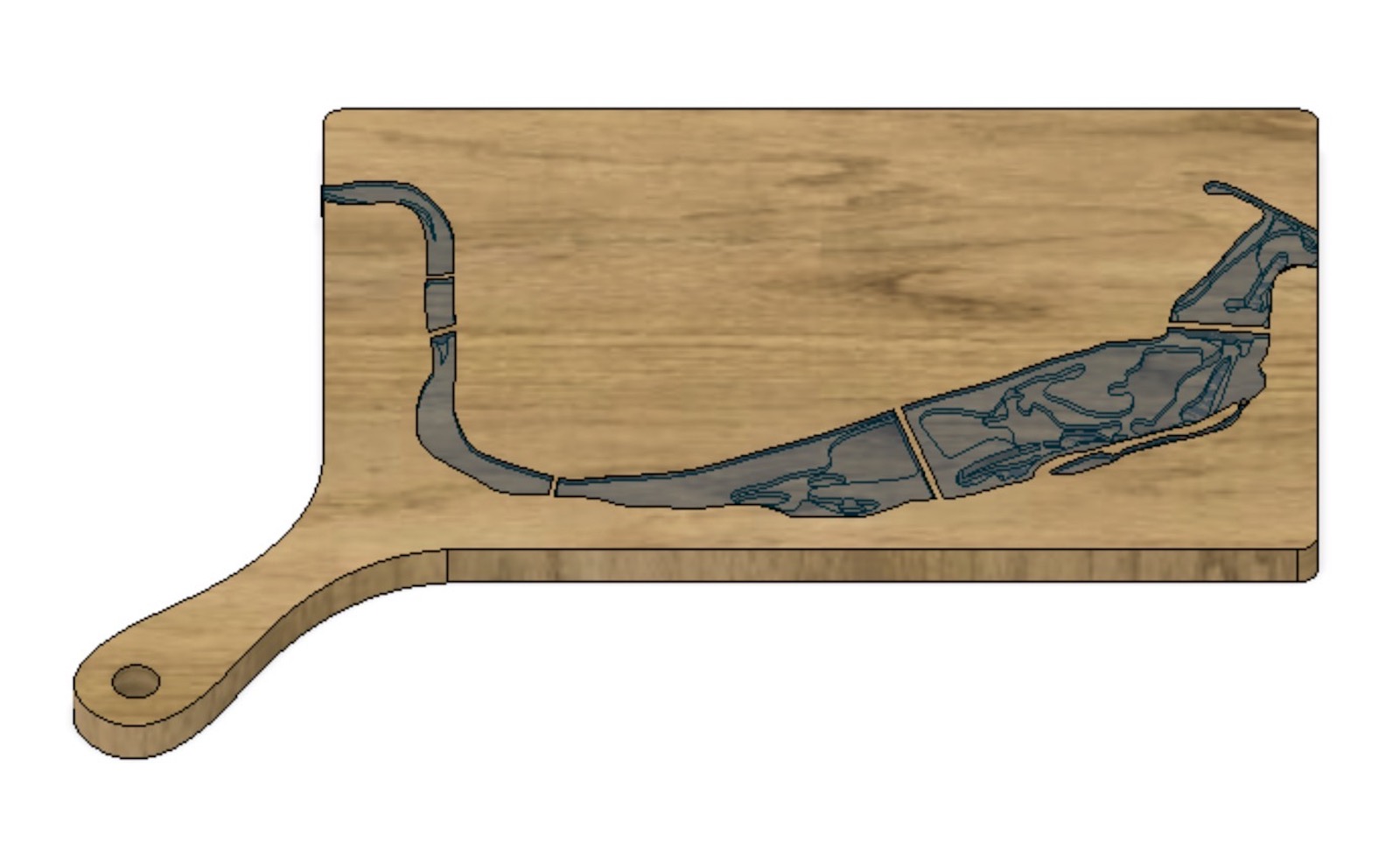

Kitchen Canvas

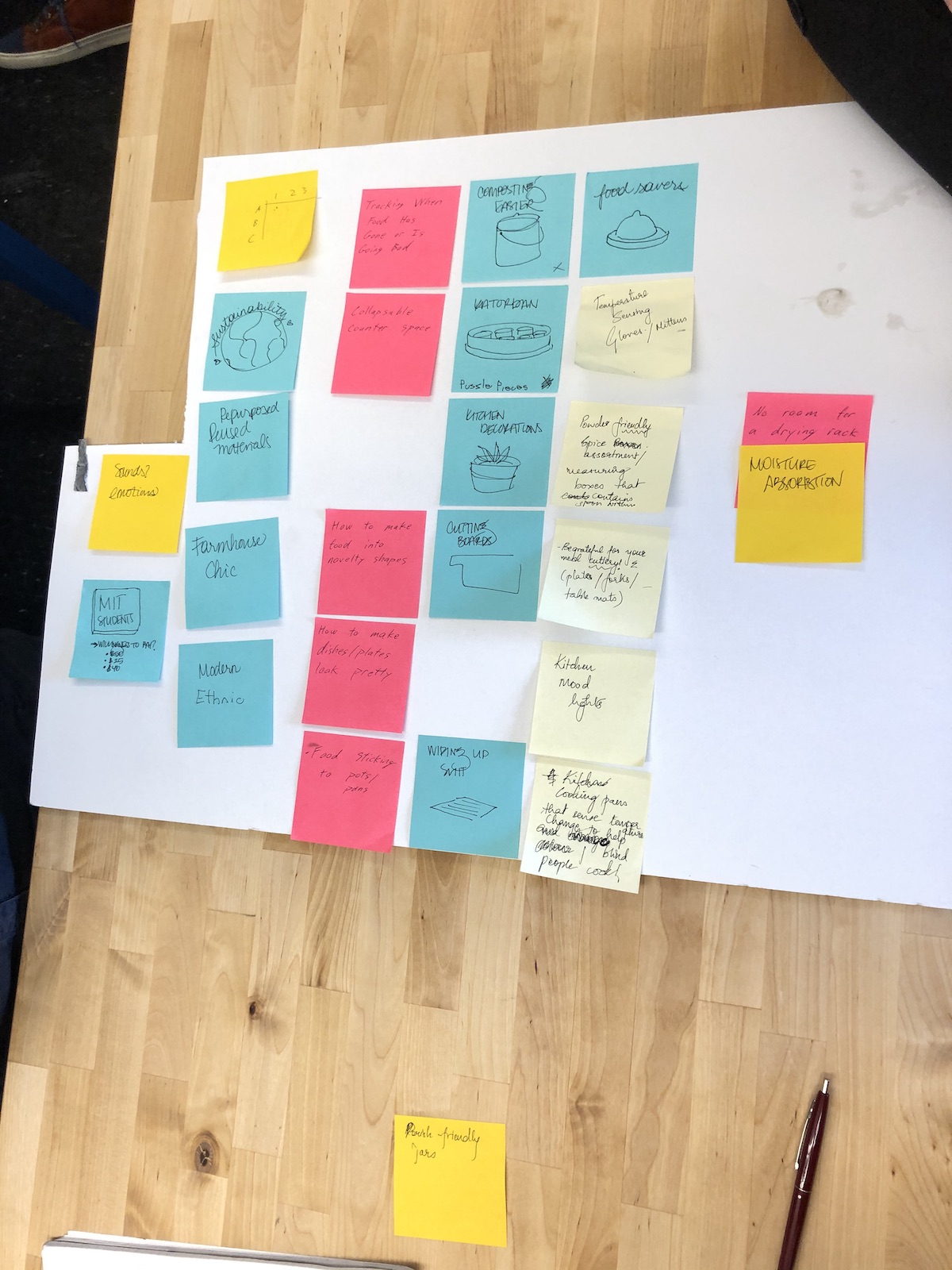

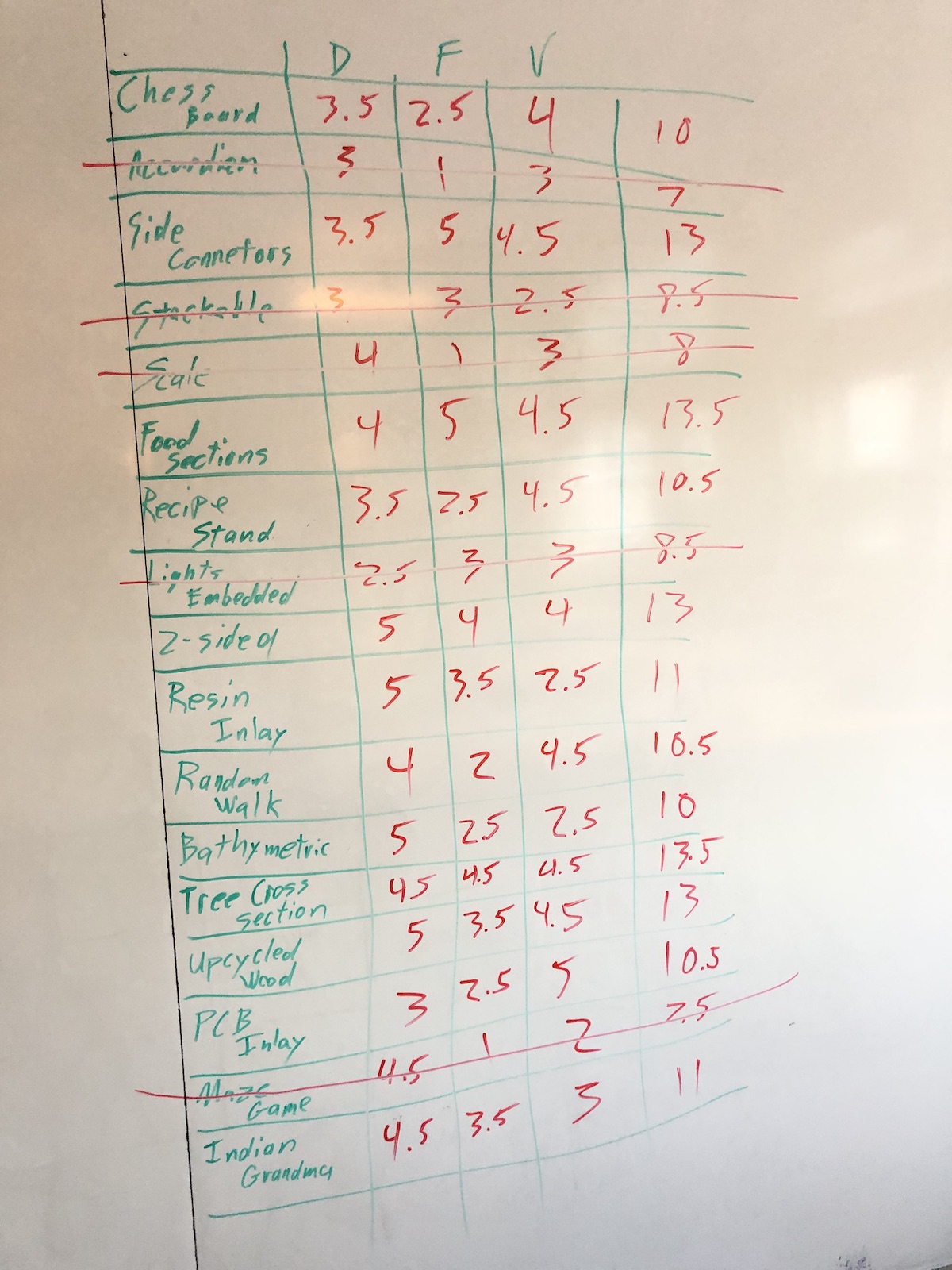

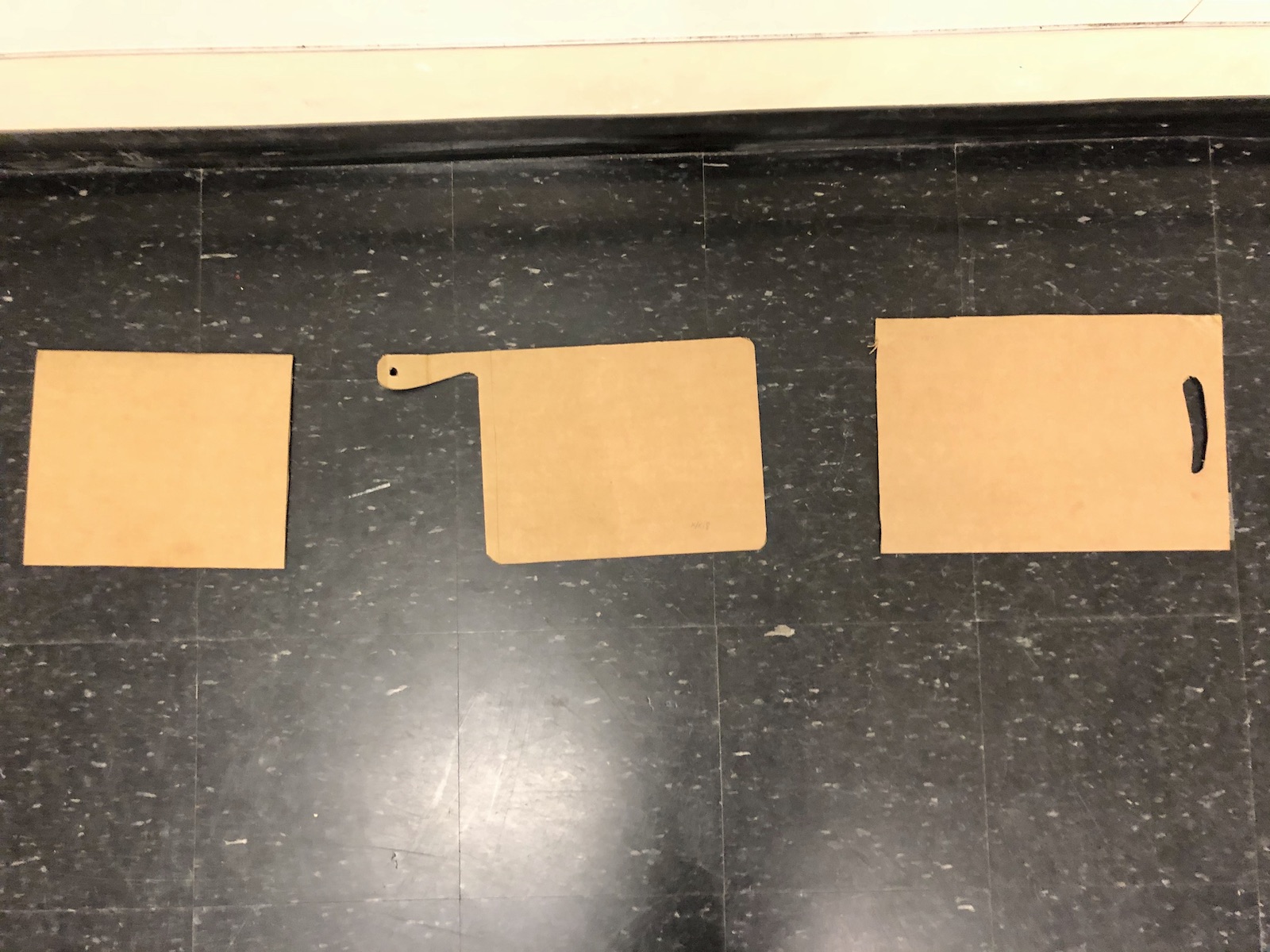

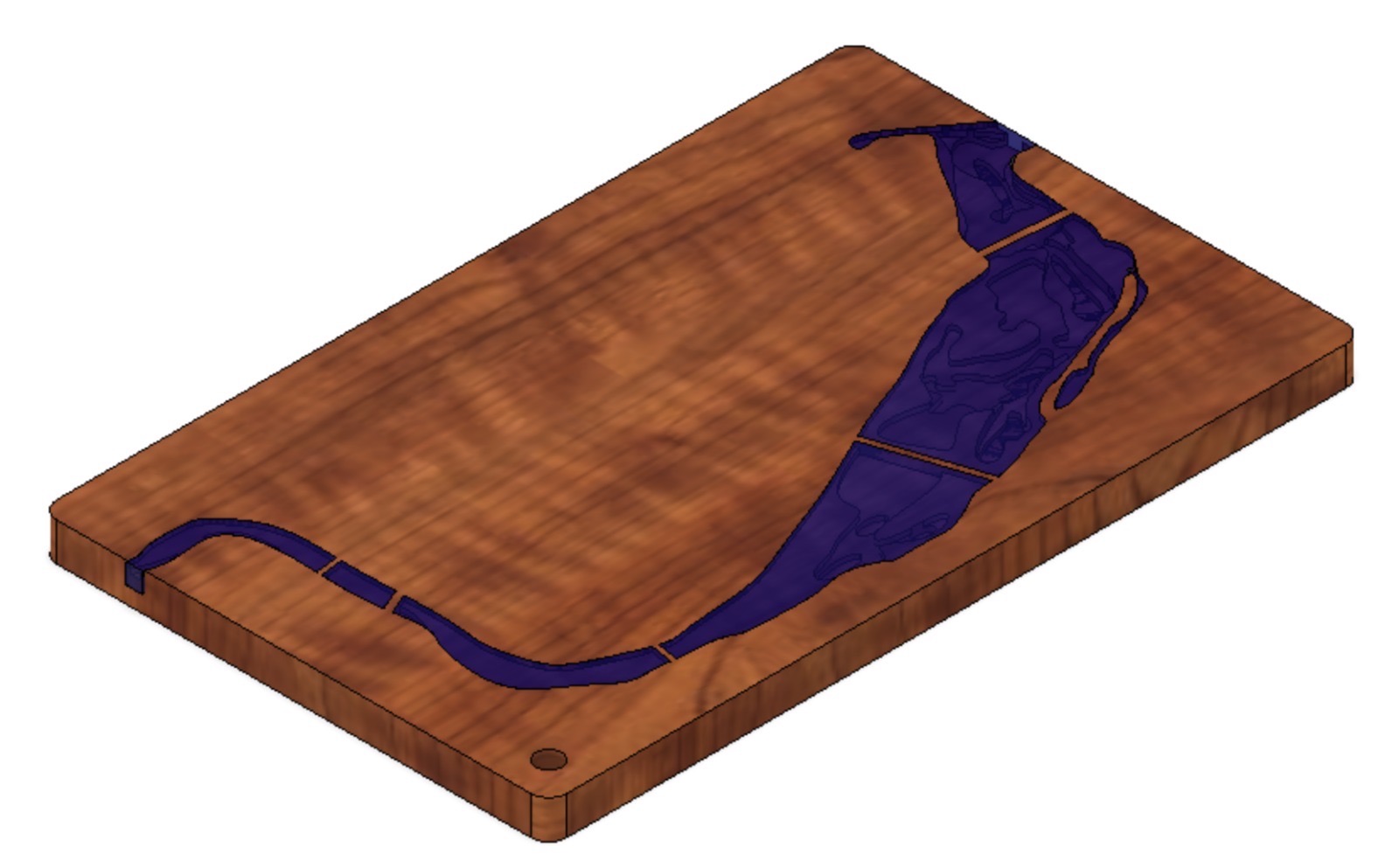

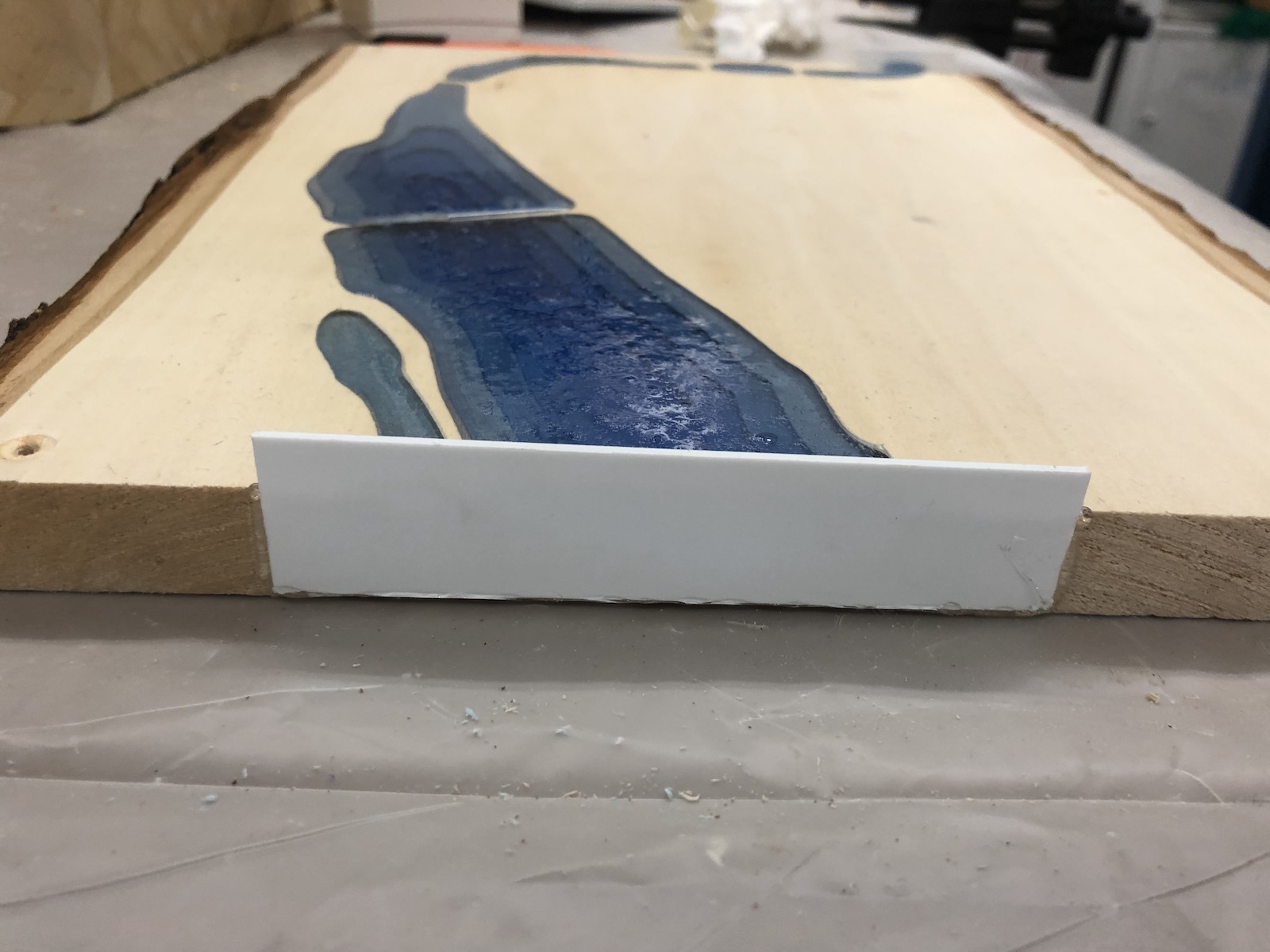

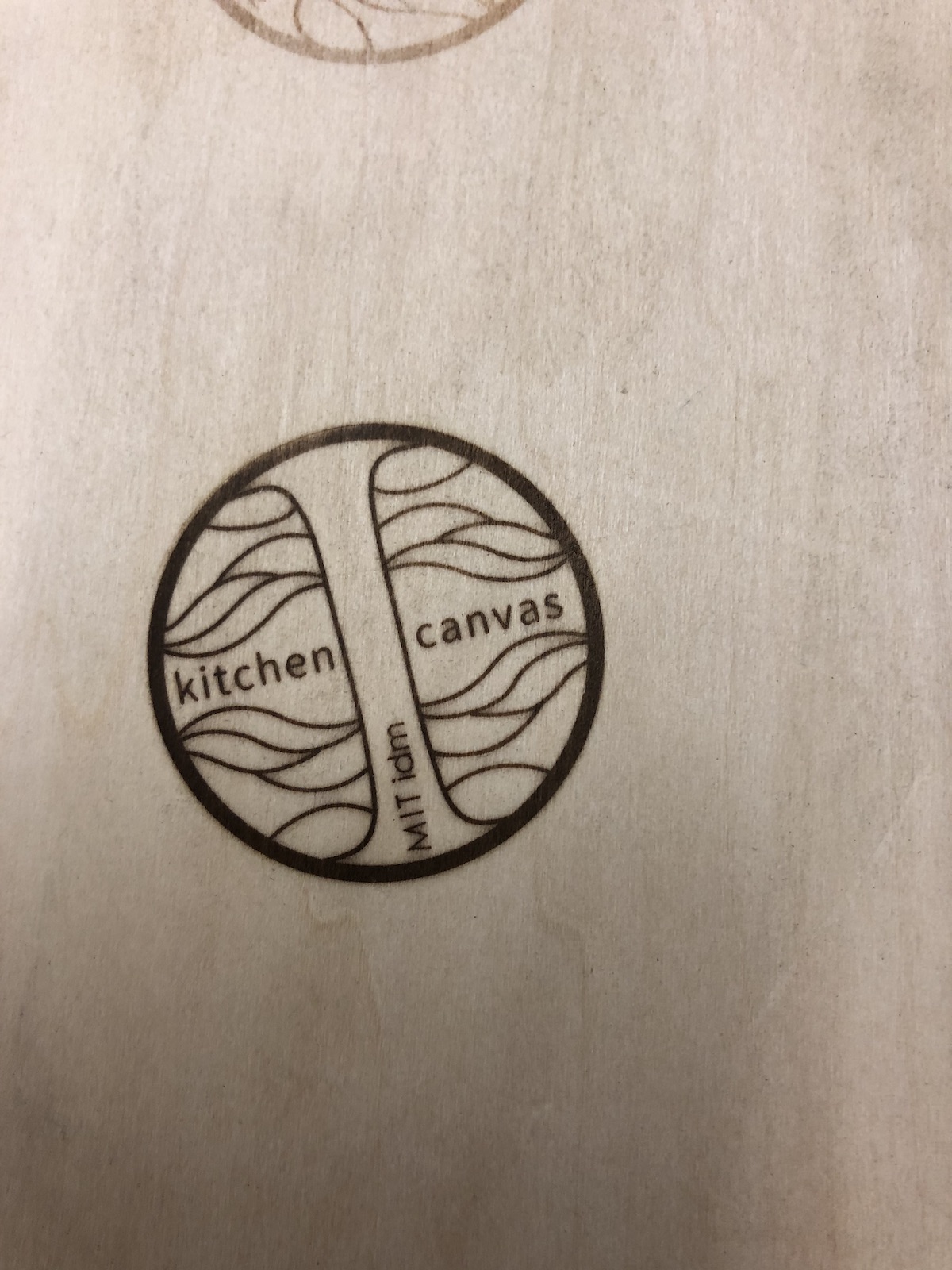

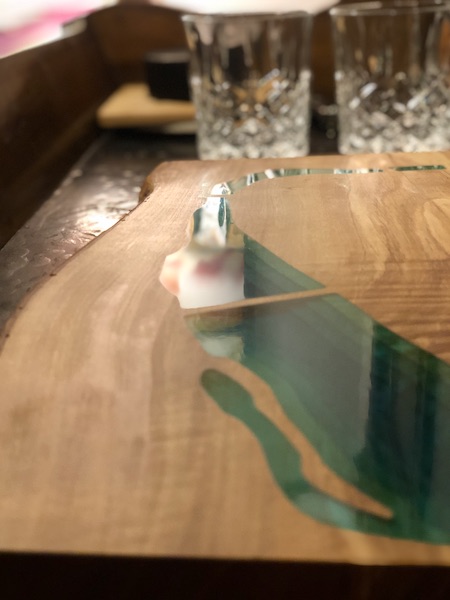

Kitchen Canvas is a product that I designed along with two other students in the Integrated Design & Management program at MIT. The assignment was to design a kitchen product that we would need to subsequently manufacture and sell 50 units of, all within a seven week time frame. The project culminated in a sales gala on Dec 11th at MIT Sloan where we sold out the remaining units of our product.

- Product Design

- MITidm

- Woodworking

- Kitchenware