See some of my past work

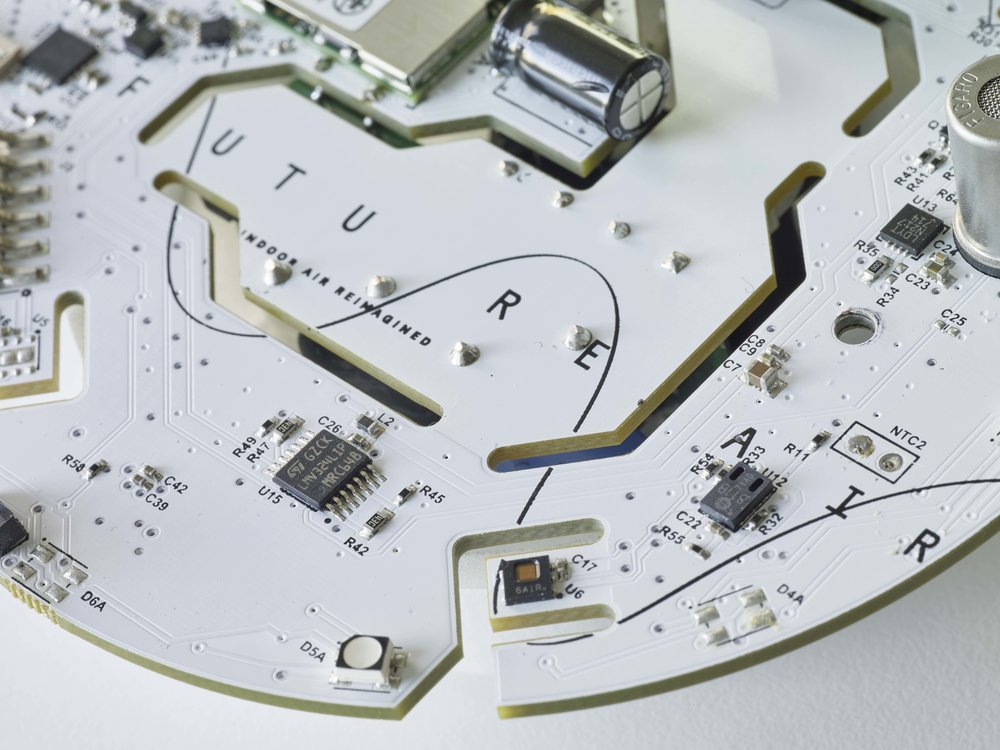

FutureAir needed a quick revision of an R3 board to be able to launch pilots on short notice.

About Project

Volta was testing a new lab-on-a-chip concept and needed a first revision plus analysis.

About Project

GEM was considering which new products to launch when, and how to evaluate which product features were necessary.

About Project

Cytera needed someone to commission and debug their cell culture automation equipment and install it at a pharma company in Boston.

About Project